PRODUCTS > Products > Vapor Barrier (Laminated Insulation Facing) > Heat-Sealing Foil-Scrim-Kraft Facing

FKSE-7511B

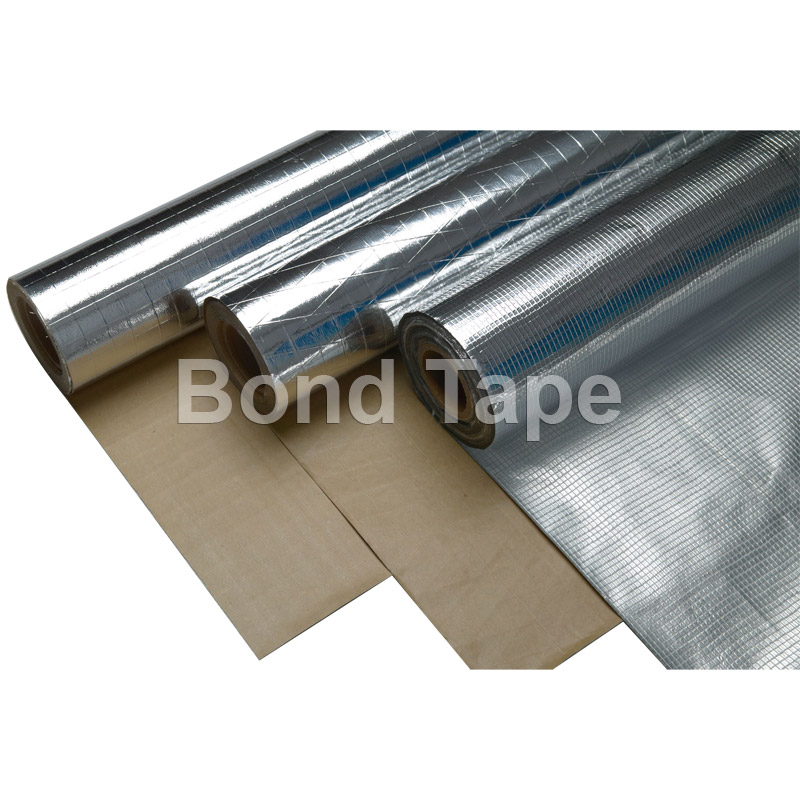

Product & Application

A utility grade Heat-Sealing Foil-Kraft-Scrim Facing with 2-way scrim and 50gsm Kraft as well as heat-activated polyethylene on its back. Suitable for in-line lamination with insulation materials by heating. No need applying extra adhesive. Good corrosion resistance.

Facing Composition

|

Facing Composition |

Description |

Value (English) |

Value (Metric) |

|

Foil |

Aluminum |

0.28 mil |

7 micron |

|

Adhesive |

Heat-Resistance Glue |

------ |

------ |

|

Kraft |

Natural |

30 lbs / 3000 ft2 |

50gsm |

|

Reinforcing - MD |

Fiberglass |

1/2 inch spacing |

12.5mm spacing |

|

Reinforcing - XD |

Fiberglass |

1/2 inch spacing |

12.5mm spacing |

|

Heat-Activated Coating |

Polyethylene |

0.8 mil |

20 micron |

Typical Physical Properties

|

Physical Properties |

Test Method |

Value (English) |

Value (Metric) |

|

Basis Weight |

Scale |

20.4 lbs / 1000 ft2 |

100 gsm |

|

Permeance (WVTR) |

ASTM E96, Procedure A |

0.02 perm |

1.15 ng/N.s |

|

Tensile Strength - MD |

ASTM D828 |

28.4 lbs/In |

125 N/25mm |

|

Tensile Strength - XD |

ASTM D828 |

16 lbs/In |

70 N/25mm |

|

Burst Strength |

ASTM D774 |

43.5 psi |

30 N/cm2 |

|

Low Temperature Resistance |

ASTM D1790 4 hrs @-40 °F (- 40 °C) |

Remains Flexible No Delamination |

Remains Flexible No Delamination |

|

High Temperature Resistance |

ASTM D1790 4 hrs @ +240 °F (+116 °C) |

Remains Flexible No Delamination |

Remains Flexible No Delamination |

|

Dimensional Stability |

ASTM D1204 @ 150F (65C) |

Less than 0.5% |

Less than 0.5% |

|

Emissivity |

ASTM E408 |

0.03 |

0.03 |

Available Roll Width: 1.2m, 1.22m

Remarks

1. The data above are typical values only, and should not be used for specifications purpose.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm; Length: Log Roll: ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature, kept away from wet and heat source.

4. The users should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for their special purpose and technique.

苏公网安备 32028102000993号

苏公网安备 32028102000993号